Font Size:

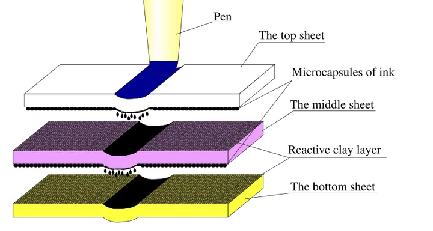

Take the picture above as an example. The back of the first paper is coated with microcapsules, and the front of the second paper is coated with a developer. When writing, the pressure of the nib breaks the microcapsules, and the dye precursors in the microcapsules contact the color developer to develop color, so as to achieve the effect of copying.

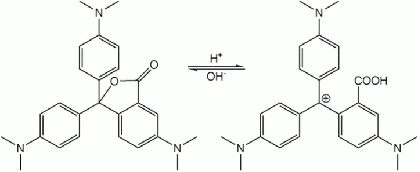

Carbonless copy paper, as the first chemical pressure-sensitive recording paper, was invented in 1954 by Lowell Schleicher and Barry Green of the NCR (National Cash Register) company in the United States. Microcapsules on the back of carbonless copy paper. Early microcapsules were prepared by precipitating water-soluble polymers (such as gelatin, gum arabic, and esterified cellulose) on the surface of organic microemulsion droplets containing dye precursors. The precipitation process is regulated by pH and temperature. The microcapsules are about 3~8 μm in diameter (the size depends on the size of the microemulsion droplet). The current microcapsules are prepared by organic polymerization between the two-phase interface (no longer the aforementioned mechanism of polymer cross-linking and precipitation), and this preparation method is more controllable. Common microcapsule "films" include polyurea, polyamide, phenolic resin, and the like. Dye precursors in microcapsules. It is called a "precursor" because it must be colorless and must become a colored dye under certain conditions. Common carbonless copy papers can choose black, blue, orange, green, red, purple, etc., correspondingly, the required dye precursors are also different. The color development of these dye precursors is pH-regulated. For example, the first dye precursor used: crystal violet lactone (CVL), under acidic conditions, the hybridization mode of the central carbon changes from sp3 to sp2, and the entire molecular structure changes into a planar aromatic structure, and its electronic excitation The state changes from the ultraviolet light region to the visible light region, that is, from colorless to colored.

The "Reactive Layer" on the front of carbonless copy paper, or the active layer. The active ingredient of the color-developing layer is a color-developing agent. Common chromogenic agents can be divided into three categories: clay type (components such as [(Mg3−zLiz)(Si4−uAlu)O10(OH)2]Mz+u+[(Mg_{3-z} Li_{z} )( Si_{4-u} Al_{u})O_{10}(OH)_{2}]M_{z+u}^{+} [(Mg_{3-z} Li_{z} )(Si_{4 -u} Al_{u})O_{10}(OH)_{2}]M_{z+u}^{+} [2]), organic type (such as phenolic resin), aromatic carboxylic acid metal salt (as zinc salicylate). These chromogens act as proton donors

Application of carbonless copy paper Carbonless copy paper is mostly used on documents. The existing formal documents with legal effect such as invoices, contracts and treaties have all used carbonless copy paper. Traditional receipts are just ordinary paper, so it is necessary to add a carbon layer under the receipt. The carbonless copy paper is bound with special paper. As far as triplet carbonless copy paper receipts are concerned, they can be divided into upper paper, middle paper, and lower paper. Upper paper is also called back-coated paper (code-named CB, namely Coated Back), the back of the paper is coated with microcapsules containing Limin pigment oil; middle paper is also called front and back double-coated paper (code-named CFB, namely Coated Front and Back), The front side of the paper is coated with color developer, and the back is coated with microcapsules containing Limin pigment oil; the lower paper is also called surface-coated paper (code name CF, that is, Coated Front), and the paper surface is only coated with color developer. Self-coloring paper (codenamed SC, or Self-Contained) is coated with a microcapsule layer containing Limin pigment oil on the back of the paper, and coated with a color developer and microcapsules containing Limin pigment oil on the front. The upper paper and the lower paper do not have the copying effect, only the middle paper has the copying effect. When using documents printed on carbonless paper, there is generally a small piece of cardboard placed on the form, so as not to write too hard and cause other forms below to be copied.

The principle of carbonless paper

2020-03-11Paper chemicals - detailed analysis of defoamers

2020-03-11Surface Sizing Process Affecting Moisture Resistance of Packaging Paper

2020-03-11Introduction of thermal & pressure sensitive dyes-ODB-2

2020-03-11What are the types of coated paper?

2020-03-11The principle of carbonless paper

2020-03-11Paper chemicals - detailed analysis of defoamers

2020-03-11Surface Sizing Process Affecting Moisture Resistance of Packaging Paper

2020-03-11Introduction of thermal & pressure sensitive dyes-ODB-2

2020-03-11What are the types of coated paper?

2020-03-11