Font Size:

Thermal paper, essential in various industries including logistics, lottery, medical, and ticketing, serves as a reliable medium for recording information. Differentiated by usage, thermal paper is categorized into two types: thermal paper without a protective layer and thermal paper fortified with one. The former, commonly found in restaurants and cash registers, lacks sufficient protection against scratches, color fading caused by ethanol, oil, or water. In contrast, thermal paper with a protective layer offers superior resistance to scratches and is highly effective in repelling water, oil, and ethanol. This variant is extensively utilized in industries such as welfare lottery, logistics labeling, ticketing, and more.

China's national standards mandate a color retention rate of ≥60% for thermal paper when subjected to ethanol with a volume concentration of 25% for three hours under standard temperature and pressure conditions, using the liquid trap method. Currently, thermal paper available in the Chinese market typically exhibits an ethanol-resistant retention rate of approximately 60%±10%. However, exposure to higher ethanol concentrations, elevated environmental temperatures during detection, or prolonged contact with ethanol can significantly diminish the retention rate, leading to the fading of printed information.

Single-proof or triple-proof thermal paper involves applying a protective coating layer on standard thermal paper. This process entails sequentially applying the filling layer, color layer, and protective layer onto the base paper.

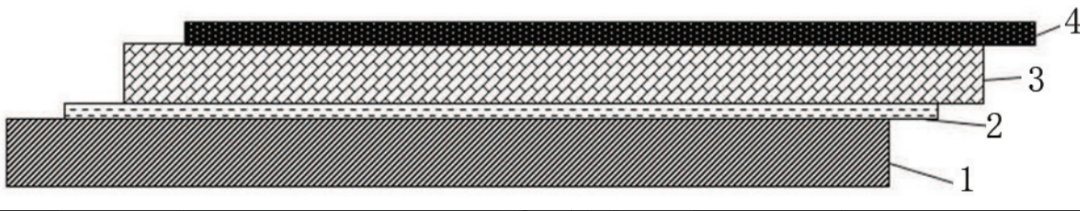

The structure of high-retention ethanol-resistant thermal paper:

1. Base paper

2. Filling layer

3. Color developing layer

4. Protective layer

Thermal paper developed by Qingdao JIERUIXIN Machinery and Technology Co., Ltd. demonstrates a remarkable color retention rate of >70% after three hours of immersion in ethanol with a volume concentration of 50%.

1. Filling Chemicals and Coating Method:

A mixture of calcined kaolin, CaCO3, polystyrene hollow sphere resin (EPS), lubricant, PVA, starch latex, additives, and water, with a solid content of 40% to 50%, is applied to the base paper using a blade coating machine at a coating weight of 4~12g/m². The thermal pre-coated paper is then formed through drying and calendering.

2. Color Developing Chemicals and Coating Method:

3. Protective Chemicals and Coating Method:

The protective layer, also known as the top coating, consists of light calcium carbonate, silica, lubricant, acrylic latex, cross-linking agent, PVA, additives, and water, mixed in specific proportions. This mixture is applied onto heat-sensitive surface coating paper using a curtain coating station, with a coating amount of 1~2g/m², followed by drying and calendering to produce heat-sensitive paper with a protective layer.

Compared to existing technologies, high-retention ethanol-resistant thermal paper exhibits exceptional stability. Even at an ethanol solution volume concentration of 50%, the printed text remains highly recognizable with a high retention rate after three hours of immersion, significantly enhancing the ethanol resistance of thermal paper and addressing the issue of handwriting fading when exposed to organic solvents such as ethanol during usage.

Sublimation Transfer Paper Structure and Related Coating Chemicals

Research progress on styrene-butadiene latex for coated paper

Carbonless paper coating chemicals components

2024-02-05The Impact of Stiffness and Density on the Quality of Coated Paper

2024-02-05Quality index of coated base paper

2024-02-05Explore the development of the thermal paper market since 2023: Trends, challenges and opportunities

2024-02-05Unveiling the Divergence: Boiler vs Steam Generator in Paper Drying

2024-02-05What is the thermal paper coating machine line?

2024-02-05Why does the thermal paper coating machine request calender?

2024-02-05Carbonless paper coating chemicals components

2024-02-05The Impact of Stiffness and Density on the Quality of Coated Paper

2024-02-05Quality index of coated base paper

2024-02-05