Font Size:

Starch plays a crucial role in various facets of the paper coating process, serving as a valuable additive to enhance the overall performance and quality of paper. The applications of starch in the paper coating process are diverse, and the following highlights the key areas where it proves beneficial:

Surface Coating: Phosphate-modified starch finds application in surface coating, contributing to improved smoothness, gloss, and printing quality of the paper. This modification facilitates the formation of a uniform, thin layer, rendering the paper surface more conducive to printing. This, in turn, reduces ink penetration and enhances image clarity.

Control of Paper Permeability: Starch proves instrumental in adjusting the permeability of paper, tailoring it for specific applications such as wrapping paper and coating paper. By judiciously varying the type and quantity of starch, the permeability of the paper can be customized to meet diverse needs.

Enhanced Paper Strength: The addition of starch can bolster the tensile strength and tear resistance of paper, imparting greater durability. This is particularly vital for applications demanding a certain level of strength, such as wrapping paper and printing paper.

Ink Absorption Control: Starch serves as a valuable tool in regulating the ink absorption of paper, ensuring even distribution during printing and preventing issues like blurring or penetration.

Increased Paper Weight: Starch is employed to augment the weight of paper, rendering it more suitable for high-quality picture or artwork printing.

Improved Printing Performance: Starch enhances the overall printing performance of paper, addressing concerns such as dust and deinking problems. This leads to an improvement in printing speed and quality.

Precision in Application: It is crucial to note that the application of starch demands precise formulation and control tailored to different paper types and process requirements. By adjusting the type, quantity, and application method of starch, the performance of diverse papers can be optimized to meet the specific needs of various industries and application areas.

Presently, we introduce a newly developed starch formulation that is tailored to enhance paper strength, improve printing performance, and reduce ink penetration—all at a more cost-effective price point.

Carbonless paper coating chemicals components

2024-01-04The Impact of Stiffness and Density on the Quality of Coated Paper

2024-01-04Quality index of coated base paper

2024-01-04Explore the development of the thermal paper market since 2023: Trends, challenges and opportunities

2024-01-04Unveiling the Divergence: Boiler vs Steam Generator in Paper Drying

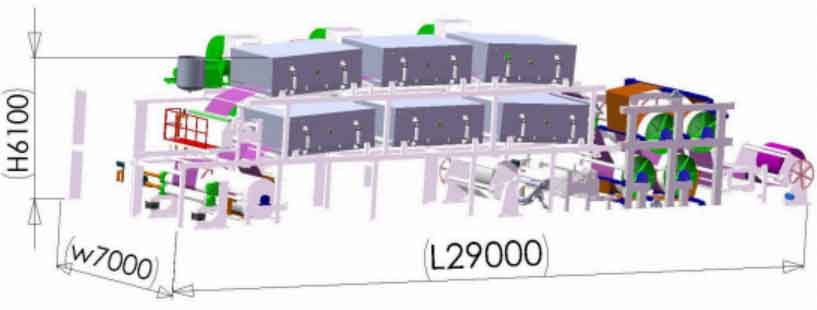

2024-01-04What is the thermal paper coating machine line?

2024-01-04Why does the thermal paper coating machine request calender?

2024-01-04Carbonless paper coating chemicals components

2024-01-04The Impact of Stiffness and Density on the Quality of Coated Paper

2024-01-04Quality index of coated base paper

2024-01-04